Custom CNC parts, also known as customized machined parts, are an essential component in the manufacturing industry. CNC machining, which stands for Computer Numerical Control machining, is a process that utilizes computerized controls and machine tools to produce custom-designed parts with a high level of precision. These parts are widely used in various industries, including automotive, aerospace, medical, and electronics.

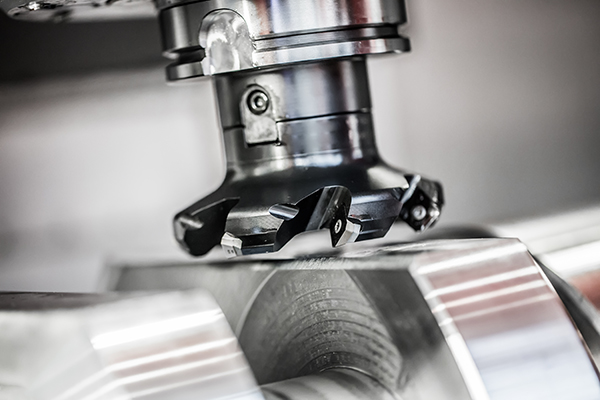

Custom CNC parts are manufactured through a process that involves the use of computer-aided design (CAD) software to create a digital model of the part. This digital model is then translated into instructions for the CNC machine, which uses a variety of cutting tools to shape the raw material into the desired form. The result is a highly accurate and consistent part that meets the specific requirements of the customer.

One of the key advantages of custom CNC parts is their ability to be tailored to the exact specifications of the customer. This level of customization allows for the creation of complex and intricate parts that may not be achievable through traditional machining methods. Whether it’s a unique shape, specific dimensions, or intricate details, custom CNC parts can be designed and manufactured to meet the most demanding requirements.

The materials used for custom CNC parts can vary depending on the specific application. Common materials include metals such as aluminum, steel, and titanium, as well as plastics and composites. The ability to work with a wide range of materials makes custom CNC parts suitable for a diverse array of applications, from lightweight components in aerospace to durable parts in heavy machinery.

In addition to the high level of customization, custom CNC parts offer exceptional precision and repeatability. The CNC machining process allows for tight tolerances and intricate details to be consistently reproduced, ensuring that each part meets the exact specifications set by the customer. This level of precision is crucial in industries where the performance and reliability of the parts are paramount.

Furthermore, custom CNC parts can be produced with efficiency and speed. Once the digital model is created, the CNC machine can rapidly produce multiple identical parts, reducing lead times and overall production costs. This makes custom CNC parts a cost-effective solution for both small-scale and large-scale production runs.

The versatility of custom CNC parts also extends to the wide range of shapes and sizes that can be achieved. From simple components to complex geometries, the CNC machining process can accommodate a diverse set of part designs. This flexibility allows for innovative and creative solutions to be realized, pushing the boundaries of what is possible in part design and functionality.

In conclusion, custom CNC parts are a vital aspect of modern manufacturing, offering a combination of customization, precision, and efficiency. Whether it’s for prototyping, production, or replacement parts, custom CNC parts provide a reliable and versatile solution for a wide range of industries. With the ability to create complex and precise parts from various materials, custom CNC parts continue to drive innovation and advancement in manufacturing processes.

Post time: Apr-01-2024