OEM Custom China Casting Machining Parts Factories Pricelist - Stamping process – GUOSHI

OEM Custom China Casting Machining Parts Factories Pricelist - Stamping process – GUOSHI Detail:

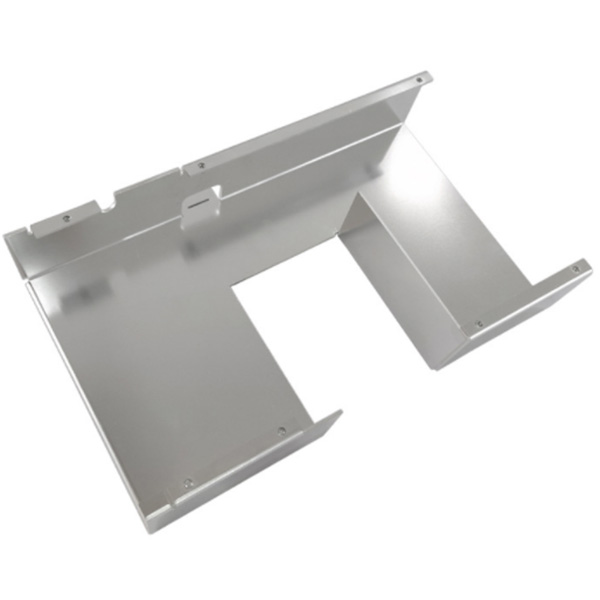

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined.

Stamping is usually done on cold metal sheet. See Forging for hot metal forming operations.

Stainless steel: SS304, SS304L, SS316, SS316L, SS303, SS630

Carbon steel: 35CrMo, 42CrMo, ST-52, Ck45, alloy steel; ST-37,S235JR,C20,C45, 1213, 12L14 carbon steel;

Brass alloy: C36000, C27400, C37000, CuZn36Pb3, CuZn39Pb1, CuZn39Pb2

Aluminum alloy: AlCu4Mg1, AlMg0.7Si, AlMg1SiCu, EN AW-2024, EN AW-6061, EN AW-6063A.

1. Bending - the material is deformed or bent along a straight line.

2. Flanging – the material is bent along a curved line.

3. Embossing - the material is stretched into a shallow depression. Used primarily for adding decorative patterns.

4. Blanking - a piece is cut out of a sheet of the material, usually to make a blank for further processing.

5. Coining - a pattern is compressed or squeezed into the material. Traditionally used to make coins.

6. Drawing - the surface area of a blank is stretched into an alternate shape via controlled material flow.

7. Stretching – the surface area of a blank is increased by tension, with no inward movement of the blank edge. Often used to make smooth auto body parts.

8. Ironing - the material is squeezed and reduced in thickness along a vertical wall. Used for beverage cans and ammunition cartridge cases.

9. Reducing/Necking – used to gradually reduce the diameter of the open end of a vessel or tube.

10. Curling – deforming material into a tubular profile. Door hinges are a common example.

11. Hemming - folding an edge over onto itself to add thickness. The edges of automobile doors are usually hemmed.

Piercing and cutting can also be performed in stamping presses. Progressive stamping is a combination of the above methods done with a set of dies in a row through which a strip of the material passes one step at a time.

Blackening stamped parts

Stamping process

Steel cold stamping parts

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for OEM Custom China Casting Machining Parts Factories Pricelist - Stamping process – GUOSHI , The product will supply to all over the world, such as: Rwanda, Victoria, Gambia, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.