ODM Famous Lapped Joint Flange Manufacturers Suppliers - Brass parts – GUOSHI

ODM Famous Lapped Joint Flange Manufacturers Suppliers - Brass parts – GUOSHI Detail:

Brass alloy is an alloy of copper and zinc, in proportions which can be varied to achieve varying mechanical, electrical, and chemical properties. It is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure.

Brass is similar to bronze, another alloy containing copper that uses tin instead of zinc.Both bronze and brass also may include small proportions of a range of other elements including arsenic, lead, phosphorus, aluminum, manganese, and silicon. Historically, the distinction between the two alloys has been less consistent and clear,and modern practice in museums and archaeology increasingly avoids both terms for historical objects in favor of the more general “copper alloy”.

Brass has long been a popular material for decoration due to its bright, gold-like appearance; being used for drawer pulls and doorknobs. It has also been widely used to make utensils due to properties such as having a low melting point, high workability (both with hand tools and with modern turning and milling machines), durability, and electrical and thermal conductivity.

Brass alloy is still commonly used in applications where corrosion resistance and low friction are required, such as locks, hinges, gears, bearings, ammunition casings, zippers, plumbing, hose couplings, valves, and electrical plugs and sockets. It is used extensively for musical instruments such as horns and bells, and also used as a substitute of copper in making costume jewelry, fashion jewelry, and other imitation jewelry. The composition of brass, generally 66% copper and 34% zinc, makes it a favorable substitute for copper based jewelry, as it exhibits greater resistance to corrosion. Brass is often used in situations in which it is important that sparks not be struck, such as in fittings and tools used near flammable or explosive materials.

| Class | Proportion by weight (%) | Notes | |

| Copper | Zinc | ||

| Alpha brasses | > 65 | < 35 | Alpha brasses are malleable, can be worked cold, and are used in pressing, forging, or similar applications. They contain only one phase, with face-centered cubic crystal structure. With their high proportion of copper, these brasses have a more golden hue than others. The alpha phase is a substitution solid solution of zinc in copper. It is close in properties to copper, tough, strong, and somewhat difficult to machine. Best formability is with 32% of zinc. Corrosion-resistant red brasses, with 15% of zinc or less, belong here. |

| Alpha-beta brasses | 55–65 | 35–45 | Also called duplex brasses, these are suited for hot working. They contain both α and β’ phases; the β’-phase is ordered body-centered cubic, with zinc atoms in the center of the cubes, and is harder and stronger than α. Alpha-beta brasses are usually worked hot. The higher proportion of zinc means these brasses are brighter than alpha brasses. At 45% of zinc the alloy has the highest strength. |

| Beta brasses | 50–55 | 45–50 | Beta brasses can only be worked hot, and are harder, stronger, and suitable for casting. The high zinc-low copper content means these are some of the brightest and least-golden of the common brasses. |

| Gamma brasses | 33–39 | 61–67 | There are also Ag-Zn and Au-Zn gamma brasses, Ag 30–50%, Au 41%.The gamma phase is a cubic-lattice intermetallic compound, Cu5Zn8. |

| White brass | < 50 | > 50 | These are too brittle for general use. The term may also refer to certain types of nickel silver alloys as well as Cu-Zn-Sn alloys with high proportions (typically 40%+) of tin and/or zinc, as well as predominantly zinc casting alloys with copper additives. These have virtually no yellow coloring at all, and instead have a much more silvery appearance. |

CuZn36Pb3 Brass

shaft parts with gearing

CuZn39Pb1 Brass

machining and knurling

CuZn39Pb2 Brass

parts for valve

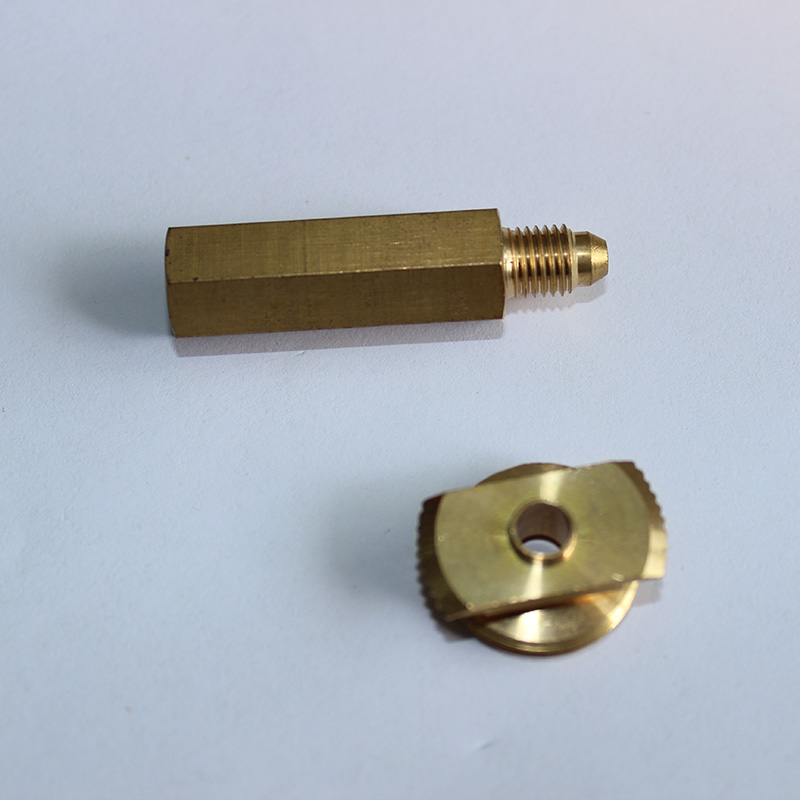

Hexgon brass

machining parts

CuZn39Pb3 Brass machining

and milling parts

CuZn40 Brass

turning rod parts

CuZn40Pb2 Brass nut

machining service

High precision

brass parts

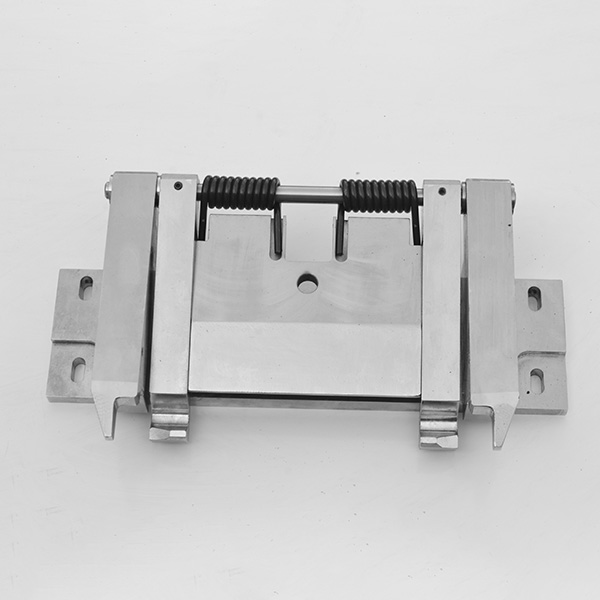

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for ODM Famous Lapped Joint Flange Manufacturers Suppliers - Brass parts – GUOSHI , The product will supply to all over the world, such as: Canberra, Malawi, Uruguay, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to supply the high-quality goods and services, and promote lasting cooperation with our customers, common development and create a better future.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.